Automation in Food Production: Revolutionizing How We Eat

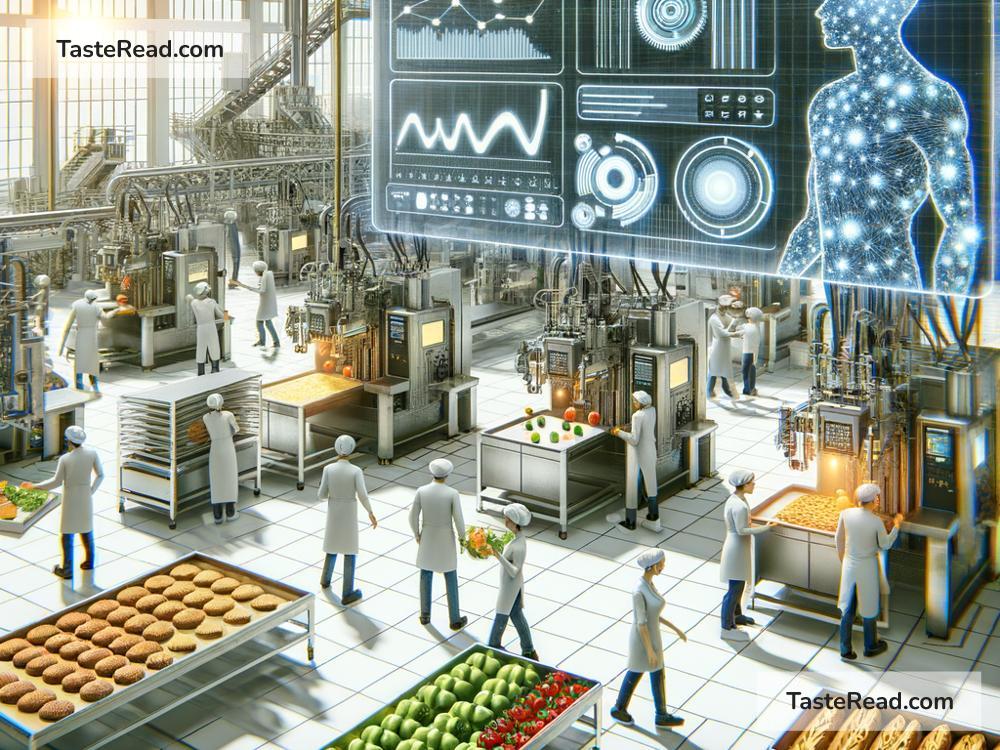

Food production is one of the most important industries in the world. Without food, we wouldn’t survive, and feeding billions of people is a big challenge. Over the years, technology has played a key role in making food production faster, safer, and more efficient. One of the most exciting advancements in this area is automation. Automation means using machines, robots, and computers to do tasks that used to be done by hand or with basic tools. In simple terms, automation has made food production smarter.

In this blog, we’ll explore how automation works in food production, its benefits, and its impact on the future of food.

What Is Automation in Food Production?

Automation refers to using advanced technology to complete tasks with little or no human involvement. In food production, this could mean using machines to process food, package items, or even grow crops. For example:

- Robots in factories can handle packaging and sorting much faster than humans.

- Automated machines can mix ingredients or cook food in bulk with precise measurements.

- Sensors and AI systems can monitor food quality to ensure it’s safe to eat.

Automation doesn’t replace human workers entirely; instead, it helps businesses produce food more efficiently and reduce manual work. This technology is used in farms, food factories, and even grocery stores, transforming every step of the food chain.

How Does Automation Work in Food Production?

Automation covers many areas of the production process. Let’s break it down:

-

Farming and Cultivation:

Automation starts on the farm. Advanced tractors can plow fields, plant seeds, and harvest crops with little need for human hands. Farmers now use automated irrigation systems that water crops based on weather and soil moisture. Drones also play a role by surveying large fields, spotting unhealthy plants, and spraying fertilizers. -

Raw Material Processing:

Food companies take raw materials, like wheat, fish, or milk, and turn them into products. For example, machines can sort fruits and vegetables based on size, color, or ripeness. In factories, automated systems grind grains, cut meat, or process dairy with precision. -

Packaging and Labeling:

Once food is ready, packaging machines handle everything from wrapping to labeling. Robots can pack snacks into boxes, seal yogurt containers, or label bottles faster than any human could. Automated labeling ensures accuracy, avoiding errors that could lead to confusion or waste. -

Quality Control:

Computers equipped with sensors and cameras can inspect food items for defects or contamination. For instance, an automated system might scan fruits for bruises or check the weight of cakes to ensure consistency. Artificial intelligence (AI) plays a big role here, helping machines “learn” to detect problems over time. -

Distribution and Retail:

Automation doesn’t stop at the factory. It helps in logistics, ensuring food gets delivered on time. Robots are now used in grocery stores to stock shelves, while online shopping platforms use automation to process orders quickly.

The Benefits of Automation in Food Production

Automation is transforming the food industry for the better. Here are some key benefits:

-

Efficiency: Machines work faster than humans. With automated systems, food companies can produce large quantities of food quickly, making it easier to meet global demand.

-

Cost Savings: Automation reduces human error, waste, and the need for labor-intensive tasks. This cuts costs for manufacturers and makes food production more affordable.

-

Improved Safety: Automated systems make food preparation and packaging cleaner and safer. Machines can handle tasks without direct human contact, lowering the chances of contamination.

-

Consistency: Human workers get tired and sometimes make mistakes, but machines can perform tasks with the same accuracy every time. This means consistent quality for consumers.

-

Customization: Smart machines and AI allow companies to create customized food products more easily. For example, machines can adjust recipes for sugar-free snacks or gluten-free bread with precision.

Challenges of Automation

While automation offers many benefits, it’s not perfect. Here are some of the challenges:

-

High Costs: Installing automation technology can be expensive, especially for small businesses. Not all companies can afford advanced machines or robots right away.

-

Job Loss: As machines take over repetitive tasks, some jobs become unnecessary. This could lead to unemployment for workers who depend on manual labor.

-

Complex Maintenance: Automated machines can break down or need regular updates. Fixing or maintaining them requires skilled technicians, adding to costs.

-

Food Waste: While automation reduces human error, improper use of technology can lead to overproduction or waste when machines run without careful planning.

The Future of Automation in Food Production

Automation in food production continues to grow, and the future looks promising. With advancements in AI, machines will become smarter, capable of predicting trends and adjusting processes automatically. For example, future systems may suggest recipes based on consumer preferences or monitor global climate changes to adapt farming methods. In urban areas, fully automated vertical farms may grow fresh food indoors year-round.

Despite its challenges, automation has the power to solve global food issues like hunger and waste. By combining innovation with responsibility, the food industry can ensure everyone has access to safe, nutritious, and affordable food.

Conclusion

Automation is revolutionizing food production, from farm to table. It helps manufacturers improve efficiency, safety, and quality while providing consumers with more reliable products. While it brings some challenges, its benefits far outweigh the downsides. As technology continues to advance, automation will play an even bigger role in shaping the future of our food system. For now, we can look forward to smarter machines making our meals better, faster, and safer than ever before.